Colt's MAXIM RT™ Regenerative Thermal Oxidizer is simple to operate, simple to maintain, and so energy efficient that it can run self sustaining without the need for auxiliary natural gas fuel for many industrial applications.

The MAXIM™ RTO utilizes the energy contained in the heat of combustion from the Volatile Organic Compounds (VOC) in the process exhaust to maintain the mandated minimum combustion chamber temperature needed for thermal oxidation.

Thermal oxidation by RTO is the most efficient method for controlling industrial VOCs.

Volatile Organic Compounds (VOCs) are gaseous emissions from thousands of different solids or liquid chemicals found in solvents, coatings, inks, adhesives, and consumer products. Read more FAQs here.

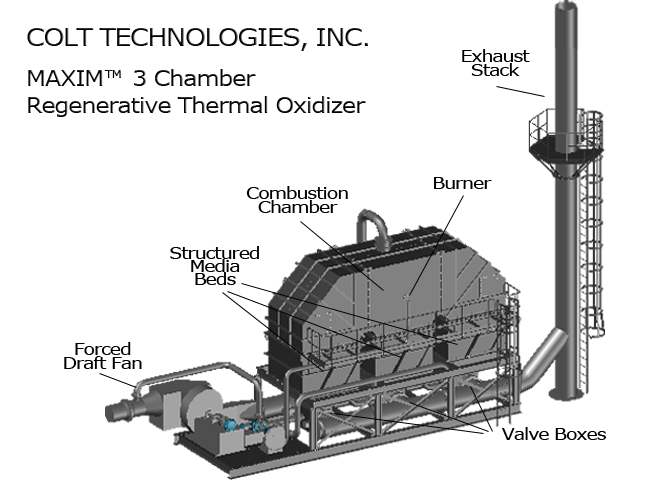

The MAXIM™ RTO's vertical heat recovery chambers contain high temperature ceramic media that recovers up to 97% of the energy generated from the high temperature oxidation process. Twin poppet style flow diverter valves located under each of the twin vertical heat recovery chambers alternate the direction of air flow (clockwise or counterclockwise) into and out of the MAXIM™ RTO on a timed cycle, thereby maintaining peak heat recovery efficiency and optimal VOC destruction performance.

The MAXIM™ RTO systems are engineered in standard modules to process 1,000 scfm to over 300,000 scfm from industrial processes. With destruction efficiency up to 99% and heat recovery effectiveness of up to 97%, the MAXIM™ RTO is reliable High Performance Control for meeting stringent State and Federal regulatory requirements for VOC, Odor, and Air Toxics destruction, while generating very low NOx, CO, and other combustion by-products.

Read about our thermal oxidizer projects.